ROLLED THREADS UNLIMITED

Company Overview

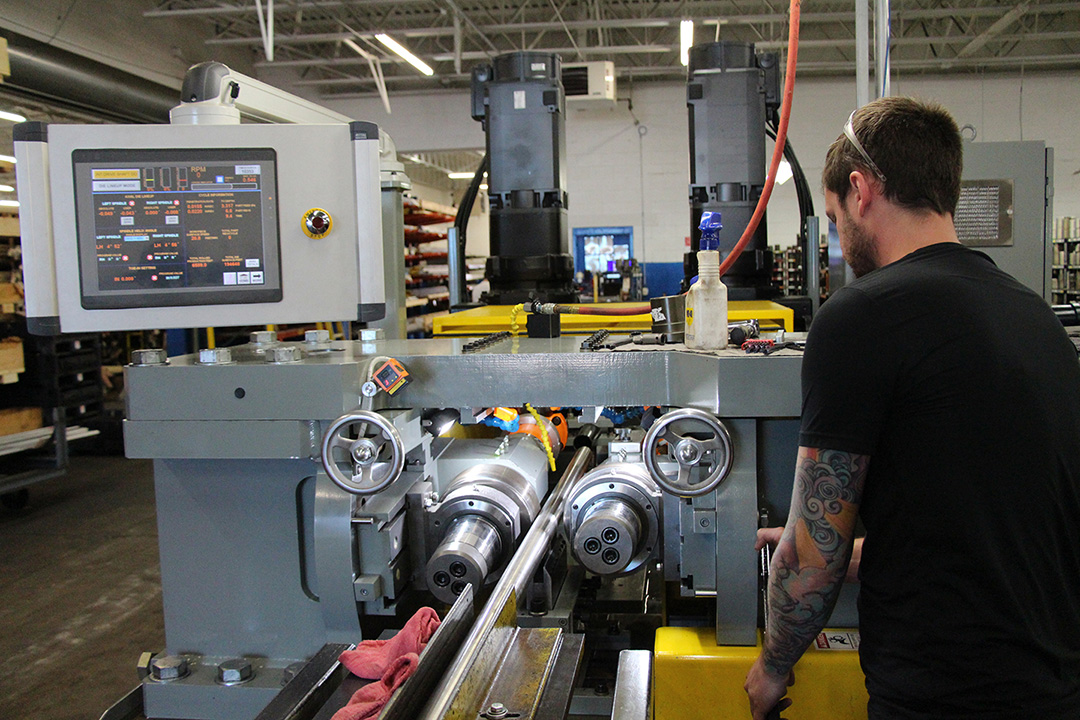

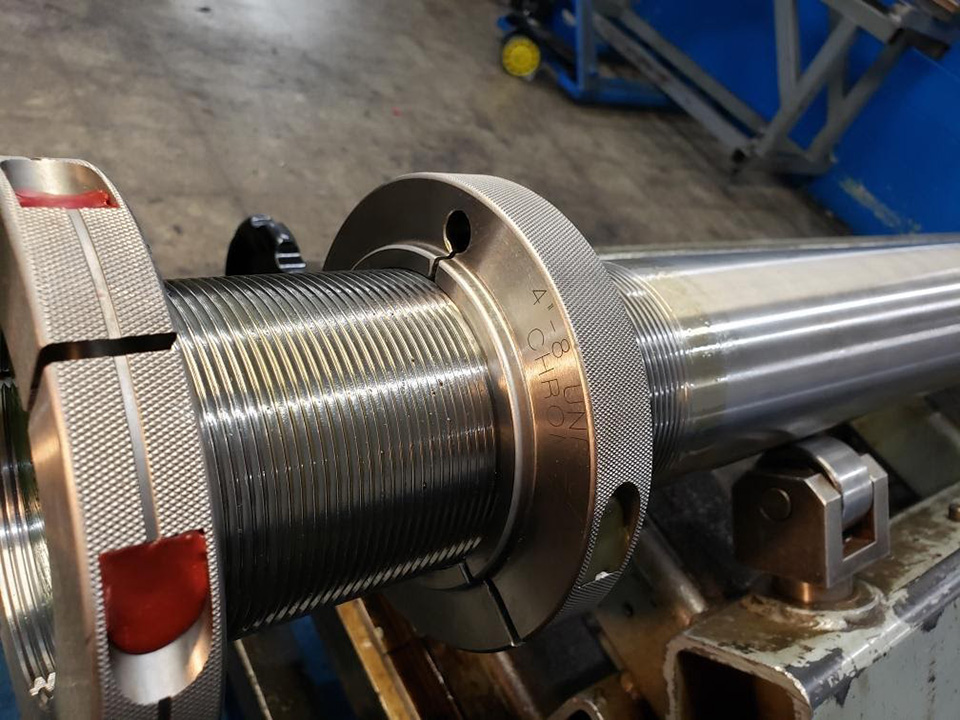

We produce fully threaded bar, custom machined parts, fully threaded and double-ended studs, bolts, lead screws, and specialty fasteners.

What sets us apart from the competition is our ability to thread super alloys, aerospace grades, non-standard stainless steel, titanium, and nickel alloys with a hardness of 42 Rockwell and higher. And while we are headquartered in Wisconsin, we serve customers across the globe.

We are also proud to provide inventory management services for our customers. We are able to produce and then store products in our warehouse so they are ready for you when you need them.

OUR VALUES

Quality

Our quality management system demonstrates our ability to consistently provide products to meet your needs and specifications.

Our History

Since our founding in 1985, Rolled Threads Unlimited has established a reputation in the metals industry as a premier thread rolling shop with unsurpassed expertise and the broadest range of capabilities.

1985

Rolled Threads Unlimited was founded by Jerry Buecher with 2 thread rolling machines in New Berlin, WI.

1987

The company moves to, and expands at, our current location in Waukesha, WI.

2002

The company is purchased by FW Ladky & Associates. Jim Ladky is named president.

2005

Rolled Threads Unlimited exceeds $5 million in sales for the first time.

2012

The company exceeds $9 million in sales for first time.

2022

Ted Ladky is named president.

2022

The company exceeds $13 million in sales for the first time.

2023

Rolled Threads Unlimited purchases 5,000 square feet of manufacturing space on its existing property.

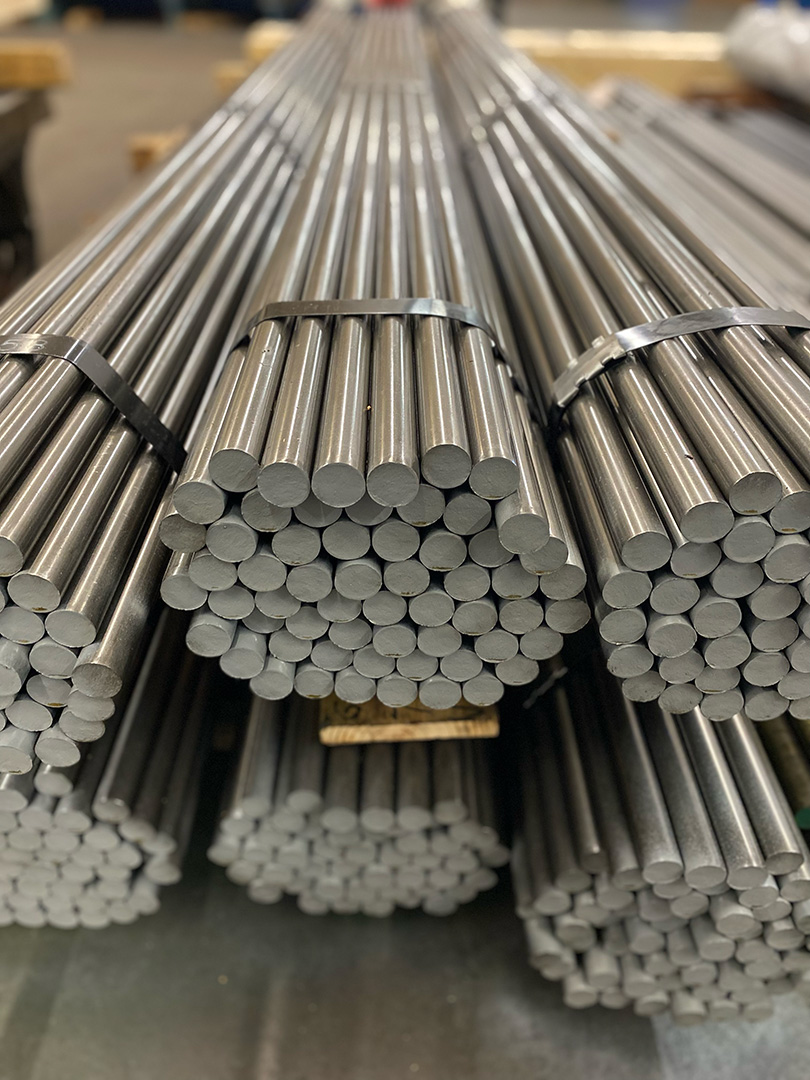

MATERIALS

A Variety of Proven Choices

We offer the following metals and alloys in varying strengths and durability. If you know exactly what you are looking for, provide us with the details. If you need help determining the right material for your project, let us be your guide.

Frequently Asked Questions

Can you provide parts complete?

Yes, in addition to our thread rolling capabilities, Rolled Threads Unlimited offers secondary services such as machining, heat treating, plating, grinding, and metallurgical and non-destructive testing to make customer parts per print.

We require material certification. Do you offer MTRs?

Yes, material certifications are provided with orders at no additional cost.

What hardness level can you roll to?

We are able to roll to Rc 42. However, the combination of the thread type and material type may restrict our ability to roll that high.

Do you stock threaded rod?

While much of our business is manufacturing parts and threaded rod custom to customer requirements, we do stock some common size acme rod in a variety of materials, as well as domestic unified threaded rod (from 3/8” to 2.50” diameter) to ASTM A193 B7 in a 3A fit.

Do you have order minimums?

For our threaded rod orders, we have a 12ft minimum order. For “roll only” or parts made complete, we do not have a minimum order quantity, but a minimum lot charge may apply.

What material types can you roll?

We roll in the following material types: low carbon, stainless steel, alloy steel, heat treated alloy, nickel alloy, brass, copper, aluminum and titanium.

Can you roll metric sizes?

Yes, we can roll threads for M4-M150+ in Metric, Metric J, and Trapezoidal forms.

Are you ISO 9001?

Yes, we are ISO 9001:2015 certified.

How are my sensitive documents kept safe?

We take protecting sensitive information like prints, purchase orders, and contact info seriously. We have recently become National Institute of Standards and Technology 800-171 compliant. This allows us to be better prepared in identifying, detecting, and responding to potential cyberattacks while protecting critical infrastructure and customer information.

Why is there a 3% charge on credit card transactions?

As of March 1, 2022, a 3% processing fee is added to all invoices paid by credit card. This change occurred due to rising transaction fees from our credit card vendors.

We thank you for understanding and truly appreciate your business. If you have any questions, please direct them to Matt Ladky at [email protected] or give our office a call at 262-547-6160.