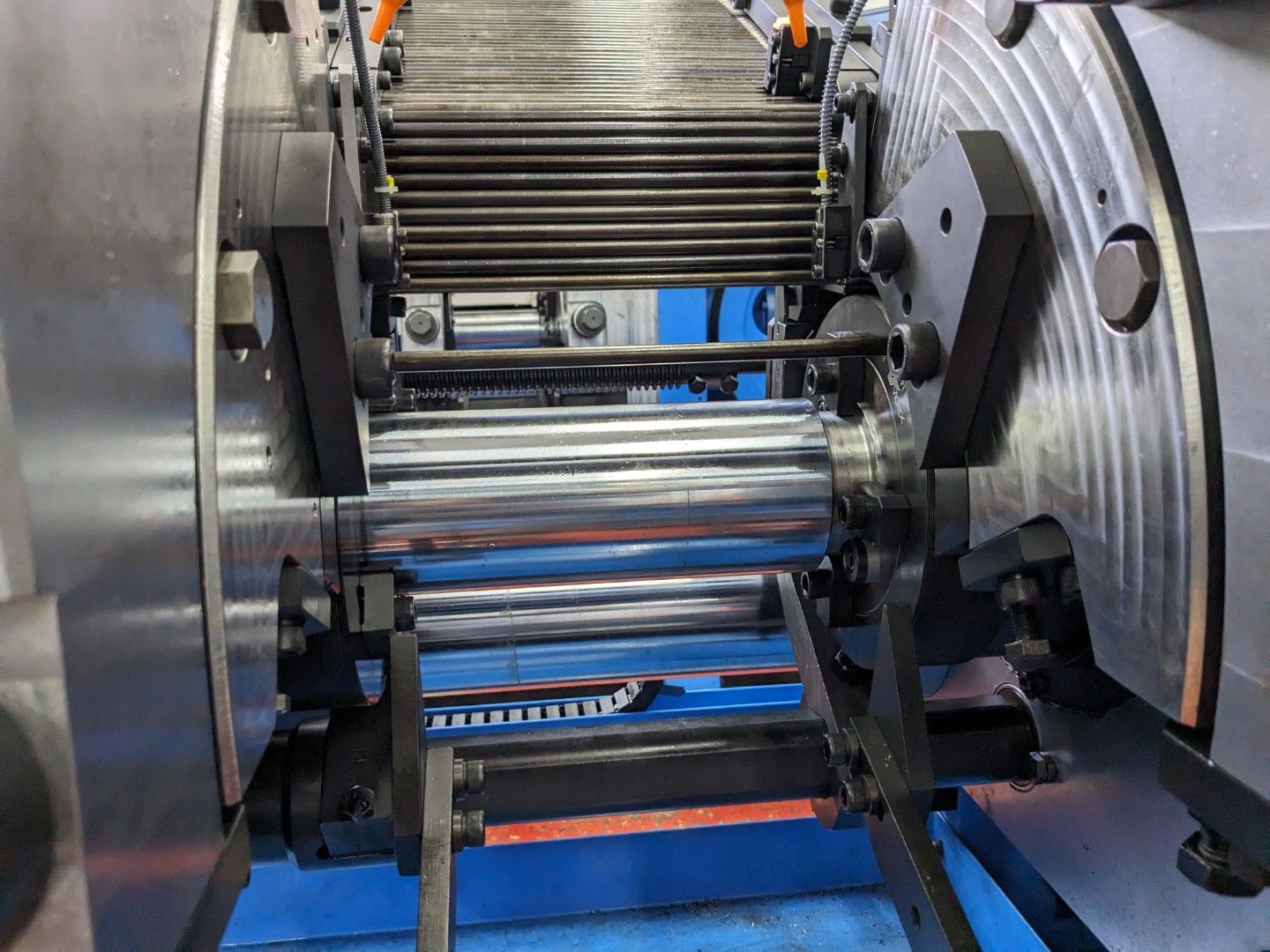

Last year, one of the machines that Rolled Threads Unlimited put into full-time production was a high-speed planetary thread roller from Videx. In line with our dedication to ongoing growth, we purchased this machine, among others, to stay at the cutting edge of thread rolling technology, accomplished in part by continuously enhancing our equipment and processes.

The Videx thread roller allows us to roll both ends of parts at the same time, resulting in a higher output at an increased speed. In fact, its production rate can vary from 20 – 200 parts per minute, depending on the part’s diameter, material, and configuration and operator speed.

Boasting wide capabilities, the machine can handle parts ranging in length from a minimum of 4 inches to a maximum of 24 inches. Additionally, there can be anywhere from 1.75 inches to 18 inches between threads.

On any given workpiece, the maximum thread length that can be rolled is 3.81 inches. When rolling threads for M16 metric threads or 5/8-inch imperial threads, the maximum achievable length is slightly shorter, at 3.15 inches. And its thread diameter capability ranges from 1/4” to 5/8”.

The Videx machine can roll both fully threaded studs and single ended studs. When rolling double-ended studs, note that both threads must have identical diameters and the same thread pitch.

The Videx threads roller is truly a versatile and reliable addition to Rolled Threads Unlimited’s equipment. Demonstrative of our commitment to quality products and customer satisfaction, its extensive capabilities could be put to use for your next component—let’s discuss your needs today.