Our commitment to precision extends beyond the products we make, it’s built into every process we use. As part of our ongoing dedication to quality and continuous improvement, we continue to invest in advanced technology that helps us maintain the highest standards our customers expect.

Our commitment to precision extends beyond the products we make, it’s built into every process we use. As part of our ongoing dedication to quality and continuous improvement, we continue to invest in advanced technology that helps us maintain the highest standards our customers expect.

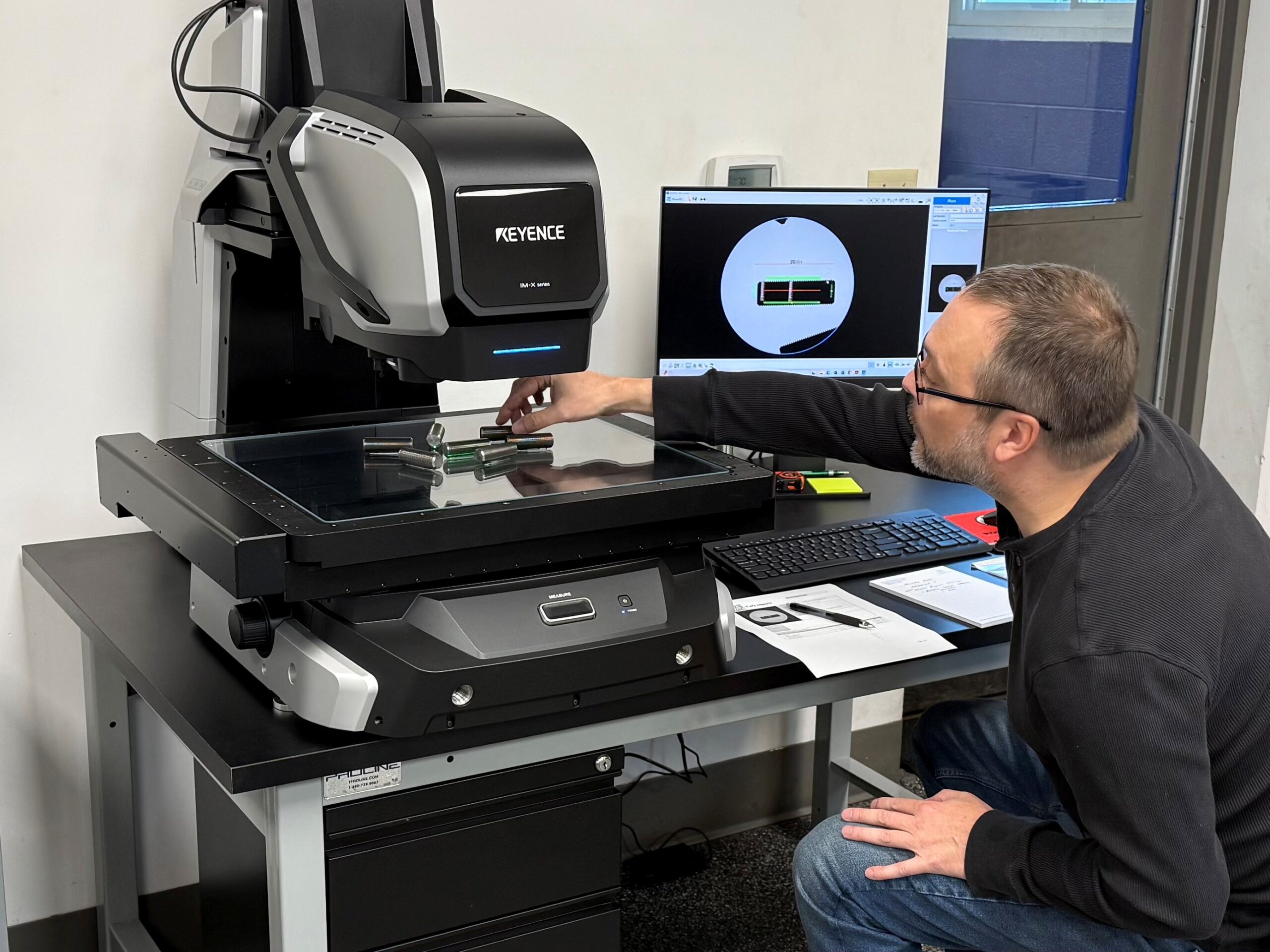

This commitment has led to the latest addition to our inspection department: the Keyence Image Dimension Measurement System (IM-X1000 Series). This advanced optical measurement system streamlines dimensional inspection by instantly measuring complex parts with the push of a button—ensuring speed, accuracy, and consistency with every reading.

Its automated focus adjustment and sub-pixel processing eliminate human error, allowing for precise, repeatable measurements regardless of operator experience. Capable of capturing up to 300 dimensions on multiple parts simultaneously, the system greatly reduces inspection time while enhancing accuracy.

Key features of the Keyence IM-X1000 include:

- Instant, one-touch measurement and automatic data recording

- Automatic drawing import and programming

- Automated edge detection and focus adjustment

- Multi-sensor capabilities including: optical, probe, laser, and 360° rotary unit for multi-surface, 3D part measurement

- Built-in statistical reporting with Cp/Cpk and trend analysis

Adding the Keyence Image Dimension Measurement System strengthens Rolled Threads Unlimited’s commitment to defect-free, dimensionally verified parts. By combining advanced measurement technology with our deep manufacturing expertise, we continue to ensure that every component we produce meets the most demanding quality standards.

We’d be happy to share more about how this system enhances our inspection capabilities—contact us today to learn more.