Free machining steels (C-12L14, C-1117, C-1141 and C-1144) are ill-suited for thread rolling operations. This is especially true for coarse thread forms such as Acme, Unified Course Series (UNC) and Worms.

Free machining steels are formulated for production on automatic screw machines. The chemistry of these grades feature high levels of sulphur, phosphorus and/or nitrogen to enhance brittleness, so the steel “chips” in the machining operations. Those attributes that enhance machinability form a coarse grain structure (1-5 grain size), with low ductility that is deleterious to any type of cold forming including bending, crimping or thread rolling.

These free machining grades will flake or exfoliate in the thread roll process and produce an unacceptable surface finish. When designing parts where a rolled thread is a key feature, free machining steel grades should be avoided. If a carbon steel must be utilized for a coarse threaded item with specific surface finish requirements, customers should consider using C-1018 or C-1045, which will produce a superior finish. The difference in surface finishes can be seen in the main photo above, which compare identical threads.

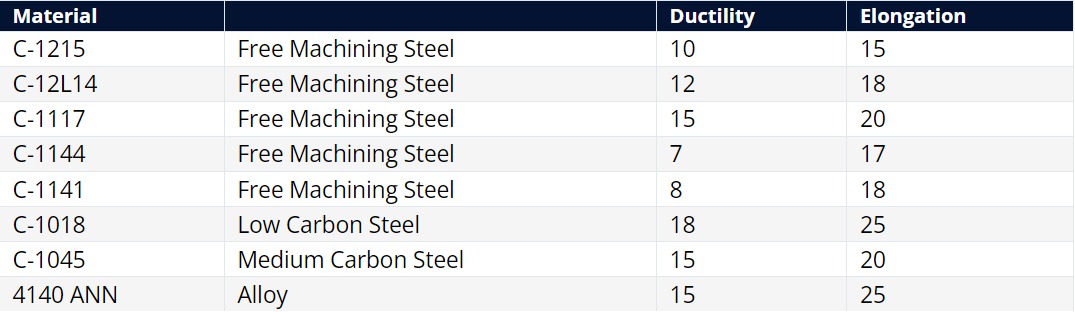

Ductility / Elongation

A measurement of the amount a material will plastically and elastically deform up to a fracture. Free machinability steels have poor elongation compared to other grades.

If you are looking for a quote on rolled Acme, Worm, or other thread forms, reach out to us today to learn more!