The integrity of every threaded fastener and component matters, down to the smallest detail. The difference between a good part and a great one often comes down to how its threads are formed. Two common methods are thread cutting and thread rolling. Both methods can create threaded forms, yet only one offers the unmatched strength, consistency, and precision demanded by critical applications.

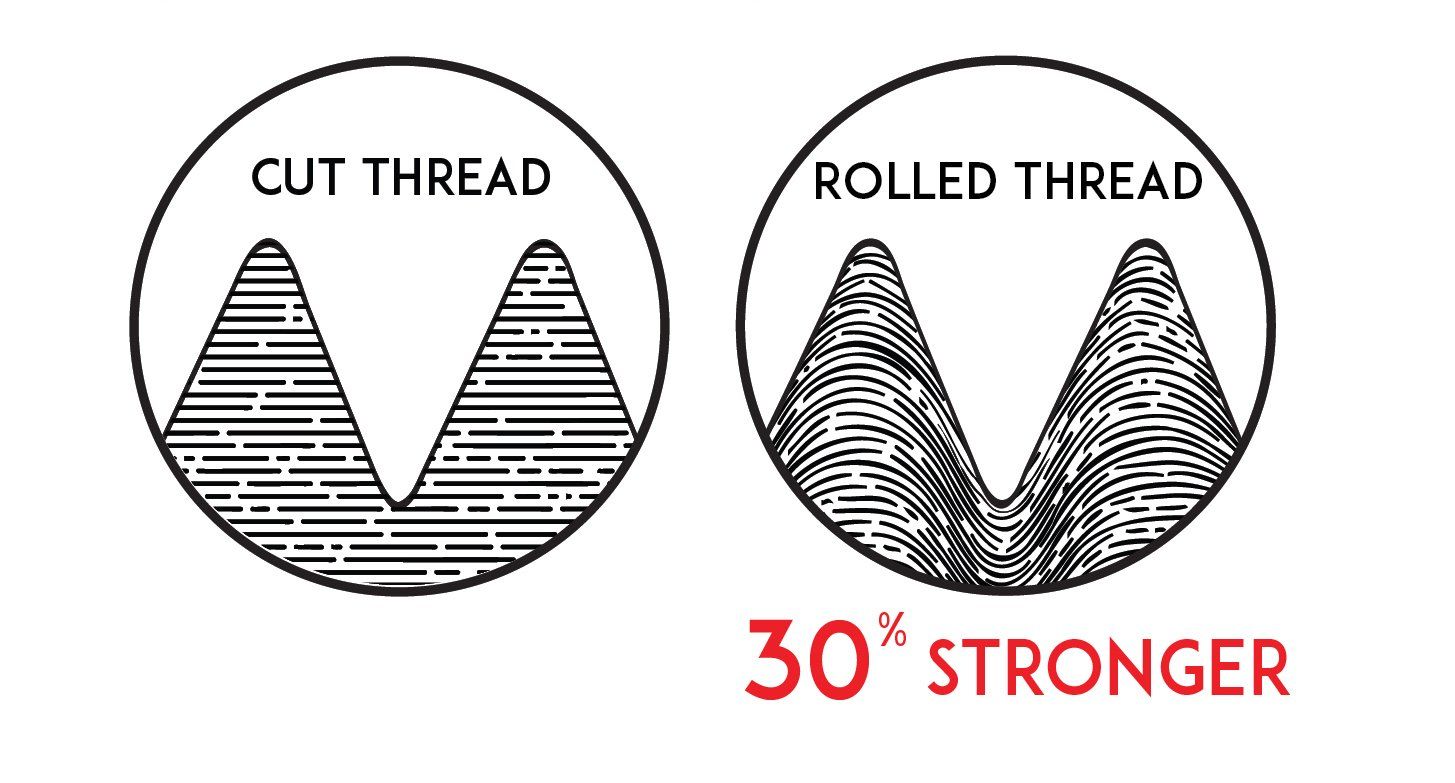

Thread cutting is a subtractive process. Material is removed from the workpiece using tools like taps, dies, or single-point cutters. Cutting disrupts the material’s grain structure, introduces stress risers, and leaves a less smooth surface finish, despite being effective for some applications.

Thread rolling is a cold-forming process. Thread rolling displaces material, which forms the thread by pressing dies against the part. This process preserves and realigns the grain flow, resulting in stronger threads with improved surface finish and fatigue resistance.

Rolled threads offer distinct advantages:

- Superior Strength: Rolled threads maintain and improve the natural grain flow of the material. This results in higher tensile, shear, and fatigue strength compared to cutting threads.

- Tighter Tolerances: Thread rolling allows for consistent thread geometry and tight dimensional control in industries where every inch matters.

- Enhanced Surface Finish: The cold-working process produces a smoother surface with fewer imperfections, which reduces friction and wear over time.

- Increased Efficiency: Thread rolling can be faster and more cost-effective in production. The tools last longer and create less waste compared to cutting methods.

Why Precision Matters

In critical infrastructure applications, failure is not an option. Rolled threads are more durable than cut threads and better suited for high-stress assemblies. Rolled Threads Unlimited brings over 40 years of specialized expertise to every part we produce. Our precision thread rolling capabilities deliver excellence that is unmatched by thread cutting.

Rolled Threads Unlimited has the ability to produce the quality of deliverables you deserve. Learn more about our wide range of product offerings.