At Rolled Threads Unlimited, we take pride in our precision, flexibility, and deep expertise. We use three core approaches to thread rolling—in-feed, thru-feed, and a combined two-step process—so you get exactly what you need, whether it’s short or long, simple or complex.

In-feed Thread Rolling

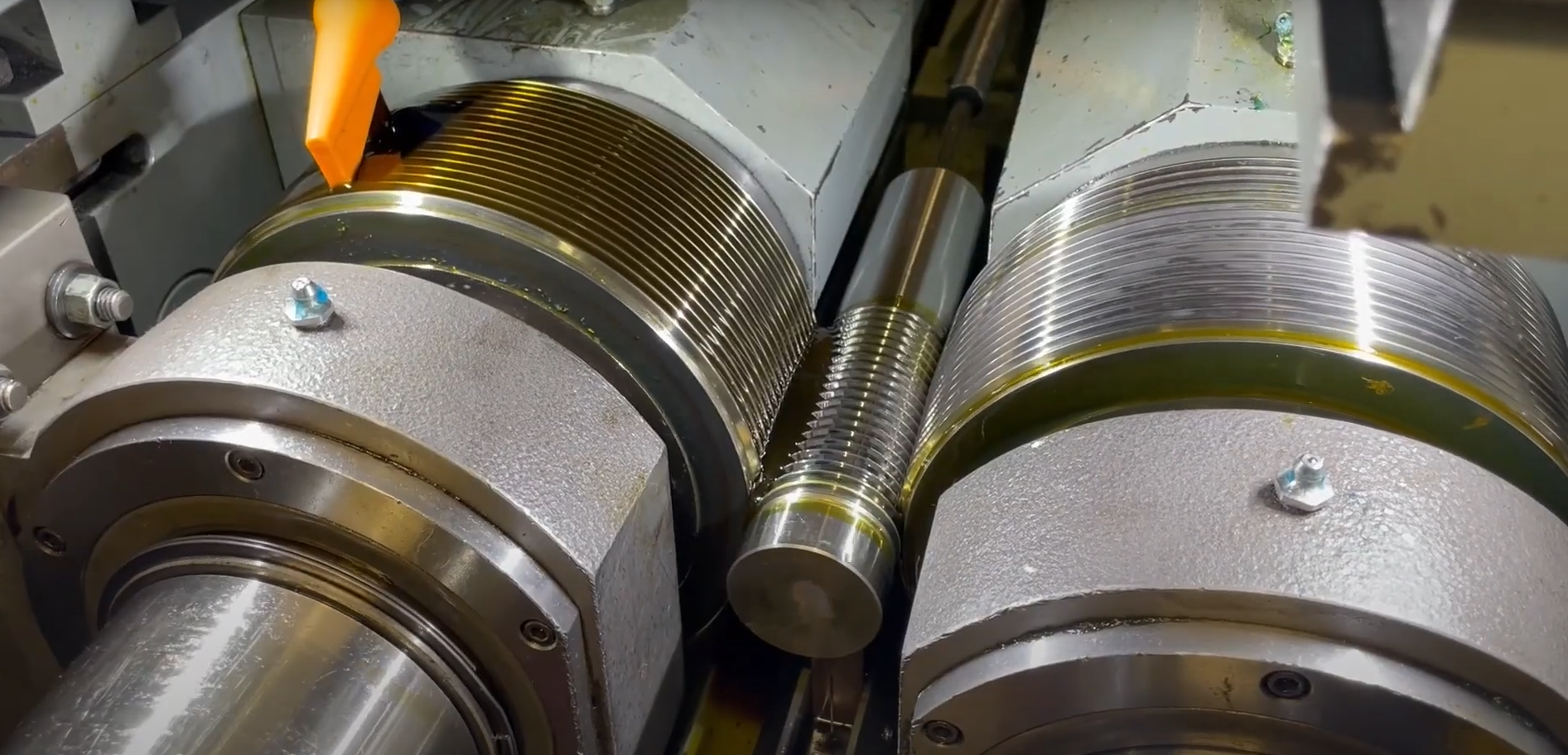

In-feed setups use two parallel dies that rotate in sync with minimal axial movement between the dies and the workpiece. Because the length of the thread is limited by the width of the dies, this technique is best suited for short thread lengths and parts that include shoulders or heads, like bolts, screws, or double-ended studs. The controlled movement allows for exceptional accuracy, making it possible to form smooth, consistent threads even in tight spaces where precision is non-negotiable.

In-feed rolling also offers efficiency for high-volume production of these smaller components. Since the thread is rolled into place with each cycle, the process can repeat quickly while maintaining uniformity across parts. For manufacturers looking for dependable, repeatable results on compact threaded products, in-feed rolling delivers both speed and accuracy without compromising quality.

Thru-feed Thread Rolling

The thru-feed process also employs parallel dies that spin together, but instead of a stationary workpiece, the part moves axially through the dies—entering on one side and exiting the other—while threads are formed along its entire length. This continuous movement makes thru-feed rolling the go-to choice for fully threaded bars or any application where the thread length extends beyond the die face. Unlike in-feed, the thread length isn’t limited by the die width, which creates greater possibilities for creating extended, uninterrupted threads.

Thru-feed rolling is especially valuable when efficiency and consistency are top priorities. The process is fast, scalable, and capable of handling larger production runs with minimal interruption. For coarse or deep threads, multiple passes can be used to ensure the required depth is achieved, while still maintaining the same smooth surface finish and strength benefits that rolled threads are known for. The result is a highly efficient way to produce longer parts without sacrificing performance or durability.

Two-Step (In-feed + Thru-feed)

Sometimes, using both methods is the best option. Especially when a specific required thread length exceeds die width and incomplete threads aren’t acceptable. We combine in-feed and thru-feed in a two-step process: starting the thread precisely and finishing it continuously. This hybrid approach allows us to meet complex requirements, ensuring both the accuracy of the thread start and the continuity of a longer run.

When it comes to thread rolling, there’s no one-size-fits-all solution. The method you choose depends on your design, performance requirements, and production goals. That’s why at Rolled Threads Unlimited, we take the time to understand your needs and match them with the process that delivers the best results. With decades of experience and a commitment to quality, we’re here to ensure your parts perform the way they should, every time.